|

Imagine! when water break at an object in sea, the force it creates. Especially,entaining or detraing the raft from barges/work-boat

is always through ladders.When ebb was high, you are high but you never know when it will go down for ebb. All of a sudden

you are at 4-5 feet down loosing grip with ladder. Either, you hit some structures near-by or tumble into water gulping few

salty drops.Is it not thrillsome.?

|

| Preparring risers |

Detecting the holidays and removing the pinholes proves effetive coating maintenance.Holidays acts as viable media to penetrate

corrosion.Outer coat may look fine but these holidays allow oxygen and increase rate of oxidation.Particularly, its needless

to say in water.Its a paramount job to detect pinholes & improve corrossion monitoring methods.

Failing to detect, allow deeper corrosion and lesser wall thickness,you never know at what time the pressurized vessel

will explode giving a change to high consequence incident.

|

|

| Clockspring Installation certificate |

Surface preparration to NACE standard was crucial to application of clads. Achieving the required standard by suitable grit

size, pressure was an another problem. Grit gets moistured, surface get wet. Weather conditions were not congenial.Bonds were

mixed and suitably applied. To maintain the VOC level of chemicals used was really difficult job- eventhough the operation

was in open-air.Boxing time was very short, application needed extreamly meticulous plan.

Throwing life boat during man-over board during ERP (Emergency Rescue Plan)used to be routine.Deck watch rehearsed atleast

once in week.Male nurse or medical practitioner carried out sebsequent inspection for the victim.Helicopter rescue was also

one of the scenario.

|

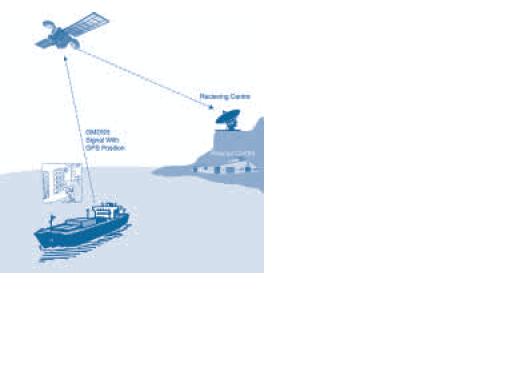

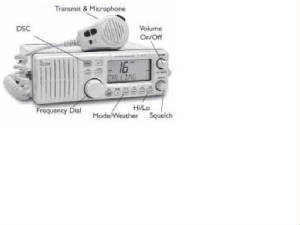

| Radar communicationSOS |

In the wider open sea, radio beacon(EPIRB),radio & helicopter were the only communication tool.Life boat, raft ,tug boat

were means to survive but those equipment help survive from unforseen clamities like fire,explosion,storm or abandon platform/barge.Beacon

when come in contact with water emits signals to nearest radar screen placed on-shore/ship close-by sailing.SOS message are

usualy sent through Radio-sets which is heared all over in the emergency channel.Listener near-by tend to rush for help.

|

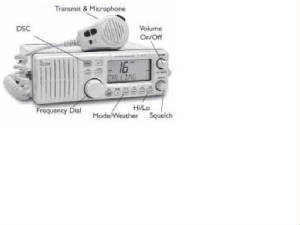

| Radioset |

Emergency helicopter services were ready on errand.Helicopter emergency rescue & escape was taught to all employee.Water

survival is purly an individual skill in the event of emergency.Radio set,radar were tuned 24 hours.Pre-boarding helicopter

& use of emengency equipment on board was briefed everytime when they board.Also, adequate number of emergency rescue

kit was equiped in all barges/ship.ERP was part of Station Bill.

|

|

| Helicopter passenger lift |

Main supply unit (i.e), risers are generally in splash zone. Repair normally pose exceptional problem. May be dent/loss of

metal or replacement.Stipulated AWS,SSPC(NACE)standard adherance in repairing is a himalayan task, demanding high skill &

experience in application.Parameter such as Humidity,Moisture,Temperature ia always present.Even divers needs high precision

to determine the riser repair.Moreover it demanded high energy from all involved.Constant waves sweeping enabled even the

scaffolders a diverse problem when erecting.Most of the time they were immersed in water.Hypothermia usually a problem experienced

by divers.Hyperbaric chambers were used to treat them as per PADI dive-table.

|

| Chamber |

|

| Chamberunit |

Installed Cofferdam when repair were in splash zone - 3 m,Artificial ventilation, gas testing was carried out.Emergency rescue

kits were positioned as per procedure, when repairing with cut & replacement.Normally divers fitted cofferdam for the

work.

|

| Underwater weld |

Underwater welding involves different safety precautions that challenge the underwater welder. In wet welding, the diver must

prevent shock hazards because underwater welding requires direct current (DC) power supply, not altnerating currents (AC).

Underwater welding also requires a knife switch to stop the current when the underwater welder is not welding. Wet welding

requires special wet welding electrodes and electrode holders exclusively designed for underwater welding. The underwater

welder also wears a rubber dive suit and gloves to avoid shock and welding lenses to filter the ultraviolet rays.

|

| Welder in cofferdam |

Mis-match,Hi-Lo of metal, Under-cut, Inclusion (slag,wagon track,hydrogen,sulphur,any such items),Poor lap ( over-lap / under

lap),Poor fusion,Burnt off(poor electrode/poor selection of current)cause poor welding & makes metal integrity less than

the original.Such things assure poor safety in pressurised vessel and leads to unexpected HCA(High consequence accident).Its

para mount importance to ensure good weld for safety.

armofi@yahoo.com

Share some of my interests? Just want to start a correspondence? Please get in touch!

Just mail to me: armofi@yahoo.com

Just click this address to send me mail:armofi@yahoo.com

|